Empowering

professionals with

real-time data insights

Sensor data analytics and infrastructure intelligence solutions created by industry leading experts.

Condition Monitoring Report 2023 – Download now.

Complete solution to monitor, analyze and

manage all sensor data

Integrate with any sensor and IoT device required by your project — no vendor lock-in

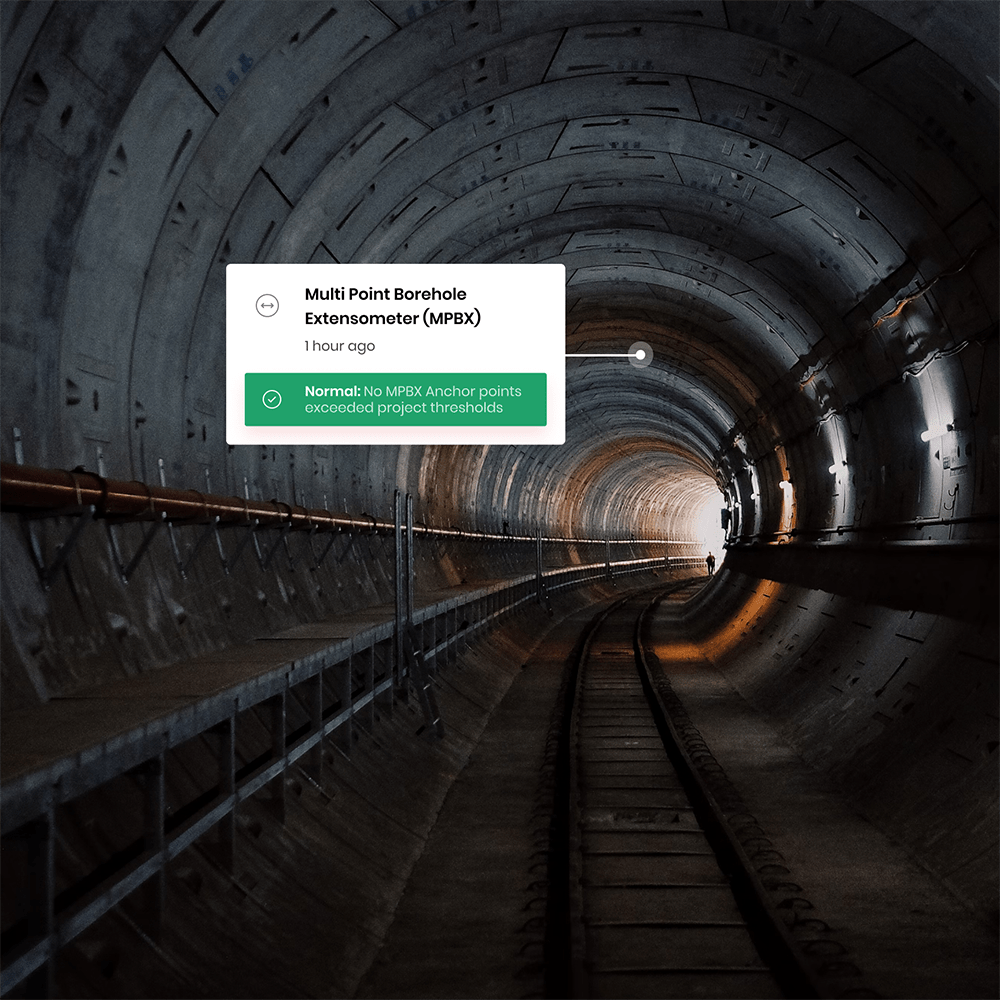

Make sense of your data with powerful dashboards, visualizations, and analytics tools

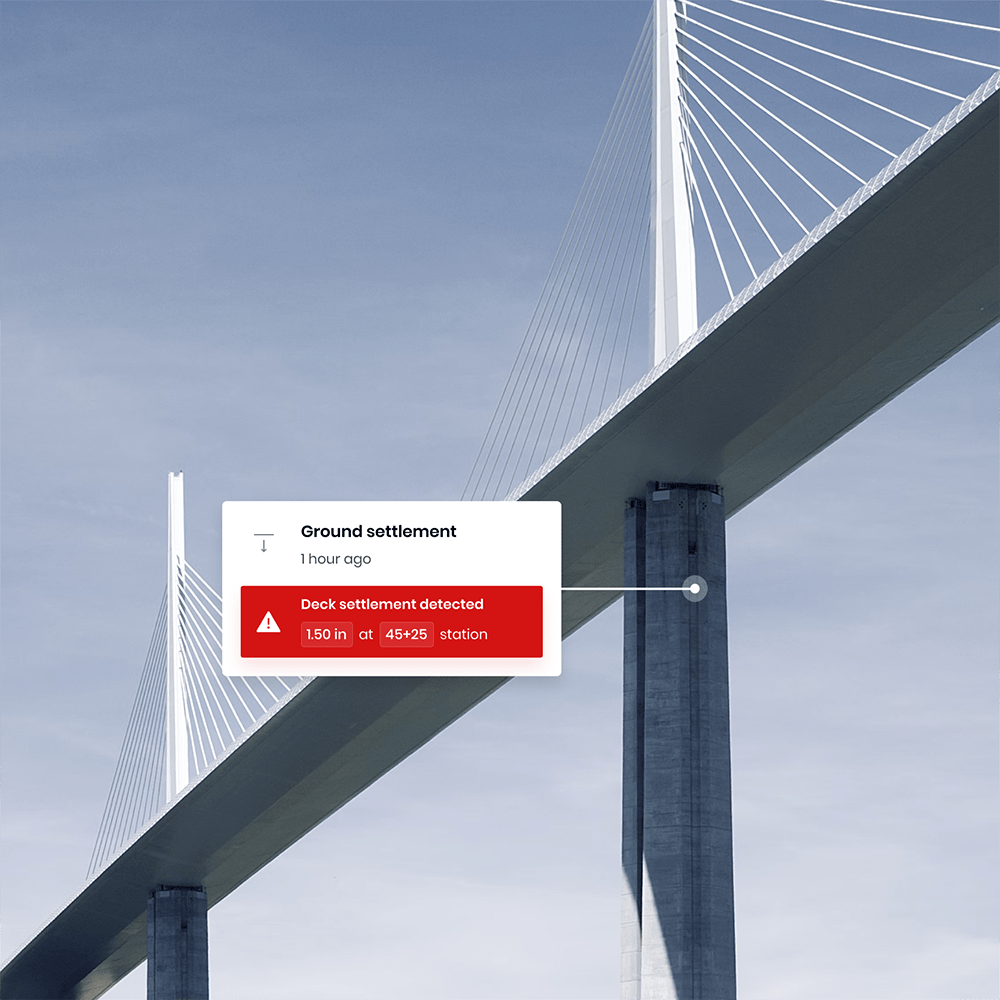

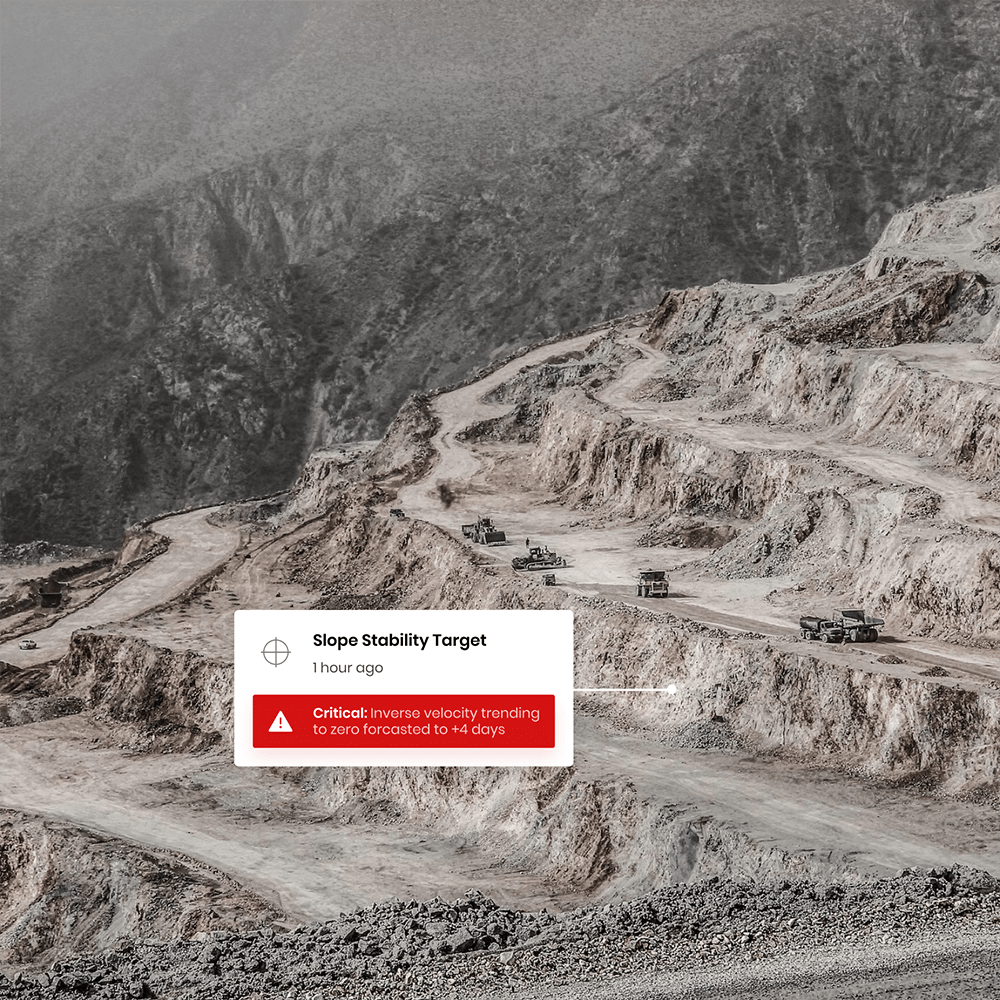

React instantly to critical sensor readings with custom alarm notifications

Keep all stakeholders informed with custom alarm notifications with fine-grained user roles and customized reports

With 30+ years of experience across industries, we’ve built a platform that fits the unique needs of each industry

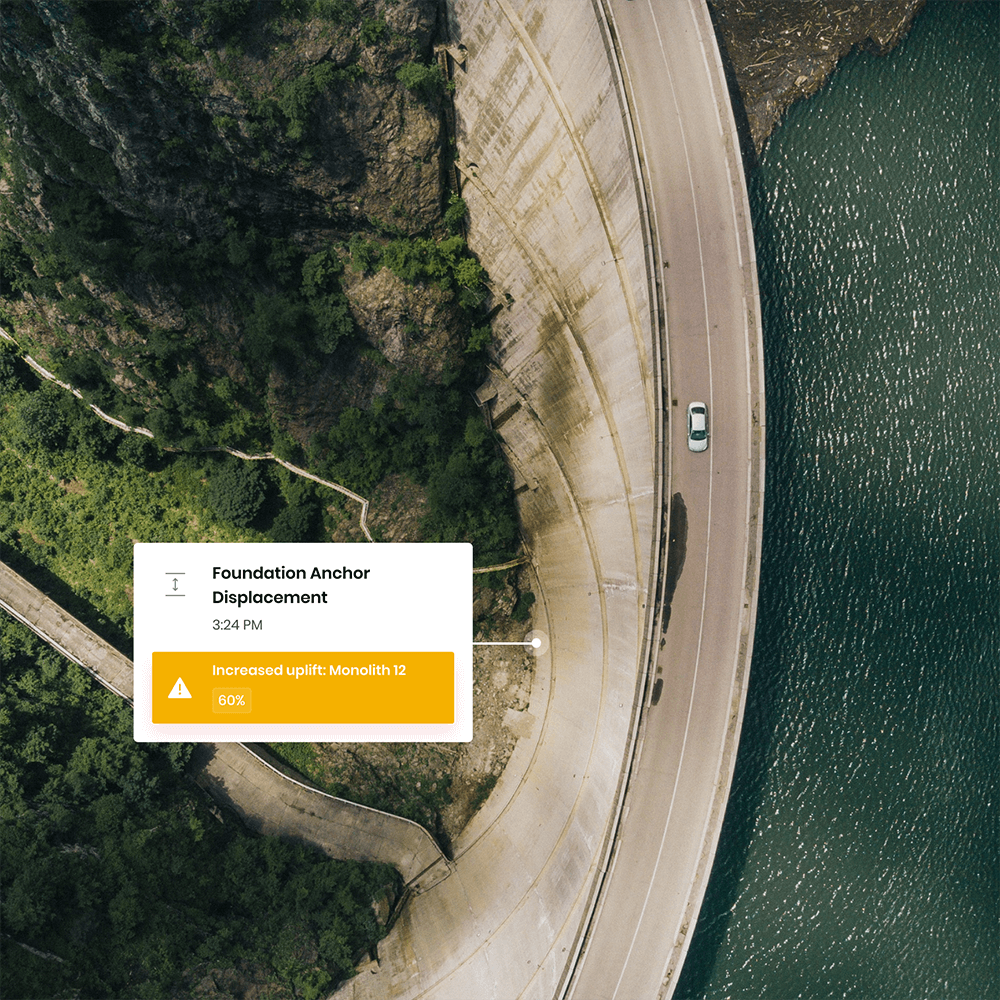

Dams

Use it with any project, of any size.

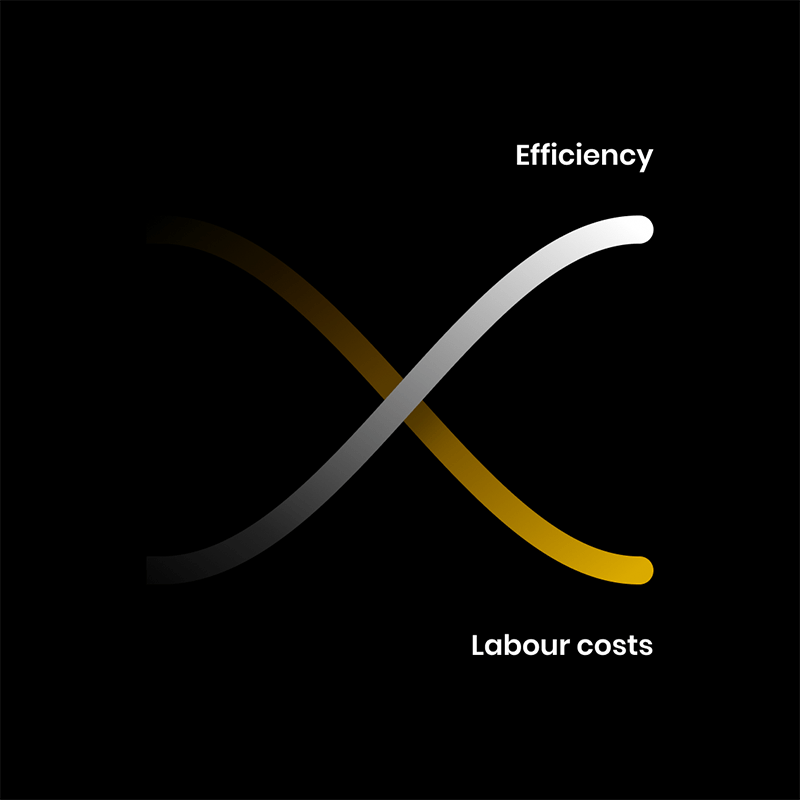

Cost effective. Improve operational efficiency and drastically reduce labor costs

Intuitive to use for all stakeholders

Fully automated

No matter your size. Be able to do your best work at any size of your company

Single or multiple projects

Tiered pricing plans

Reliable, responsive & secure. Ensure maximum uptime and security of your data

Cloud or local/offline installation

Built on the highest level of Security, Privacy and Compliance standards ensured by the Bentley Trust Center

No Vendor lock-in. Integrate with any sensor, IoT device, or data logger

| Supports all manufacturers |

Support for field data collection and manual data entry.

| Supports all manufacturers |

Get started. Our team of experts is here to help you.

Expert consultancy

Pilots or large projects

Worldwide support

Alan Jones

Senior Director, BD

Alex Pienaar

Senior Director, Sales